How can a supply chain be both efficient and responsive?

You can make your supply chain efficient and responsive through careful planning, streamlined processes, and agile adaptation to changing demands.

Published: 9 September, 2024 · 10 mins read

Supply chain leaders are facing challenges that are not letting up anytime soon. Rising costs, geopolitical unrest, transportation limitations, and component shortages make it challenging to meet the dynamic customer demands. To tip the scales in their favor, businesses can optimize supply chain workflows, introduce automation, predict demands, and take other measures detailed in our post.

With increasing customer demands, fluctuating market trends, and disruptions, businesses

continually strive for supply chain improvement to enhance efficiency and resilience. If

you're grappling with supply chain inefficiencies, you're not alone. Countless enterprises

in the sector struggle due to outdated processes, poor visibility, and rising costs.

How to improve supply chain operations amid uncertainty? Exoft is a premier

transportation software development

company. We tailor custom software, helping businesses automate tasks, reduce costs, and maximize

efficiency. Exoft can help you optimize logistical operations with state-of-the-art solutions

for fleet management, warehouse automation, and more.

This article presents key efficiency metrics and the top 10 strategies for supply chain process

enhancement and transformation. Whether you aim to reduce lead times, minimize inventory costs,

or enhance collaboration, these best practices for

supply chain system improvements

will help you achieve greater success in the market.

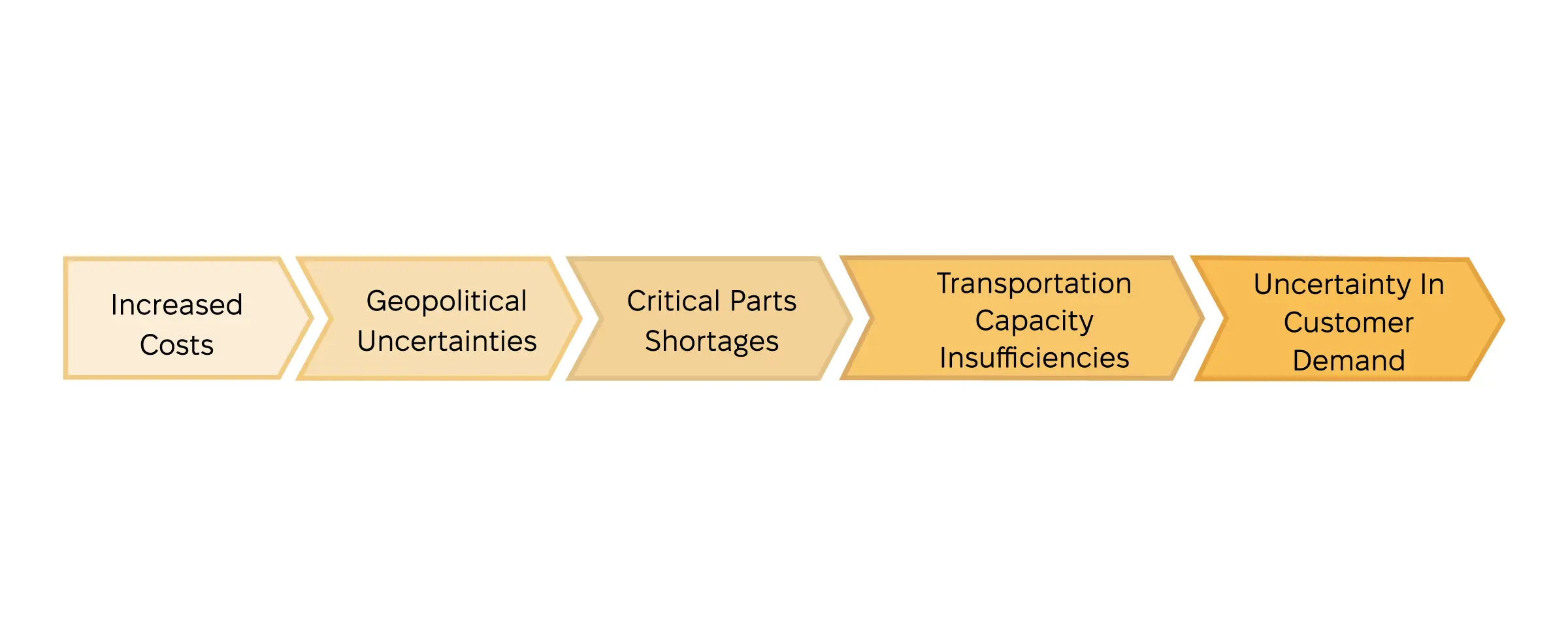

Disruption and uncertainty have become prevalent cons in the industry, with 82% of supply chain leaders expecting challenges to worsen or remain consistent in the coming months. Each of them requires innovative solutions and strategic foresight to overcome.

Supply chain leaders face a relentless cost surge, spanning raw materials, labor, transportation, and other operational expenses. These escalating costs directly impact profitability and operational viability, necessitating proactive strategies to mitigate their effects.

Geopolitical tensions challenge supply chain stability. Trade disputes, regulatory changes, and geopolitical conflicts disrupt global trade routes, networks, and sourcing strategies. These uncertainties force leaders to develop complex strategies for supply chain system improvement.

A persistent shortage of trucks, ships, and containers creates supply chain challenges. Limited transportation options lead to delays, increased costs, and inefficiencies in moving goods from outsourcing suppliers to customers, exacerbating supply chain problems.

Shortages span critical components like semiconductors, microchips, and electronic sensors to rare earth metals and specialized alloys, which are crucial for high-tech production. They disrupt manufacturing lines, leading to delays, increased costs, and compromised product quality.

Fluctuations and unpredictability in customer demand make supply chain planning and

management challenging. Rapid shifts in consumer preferences, trends, and economic

conditions require agile supply chain strategies to adapt quickly to changing demand

patterns.

How to improve the supply chain and overcome the challenges? To address them, supply chain

leaders foster strong supplier relationships, diversify their supplier base, and invest in

innovative digital solutions. Technology is crucial for improving supply chain. Tech solutions

boost agility, visibility, and uncertainty resilience, ensuring business continuity and competitiveness.

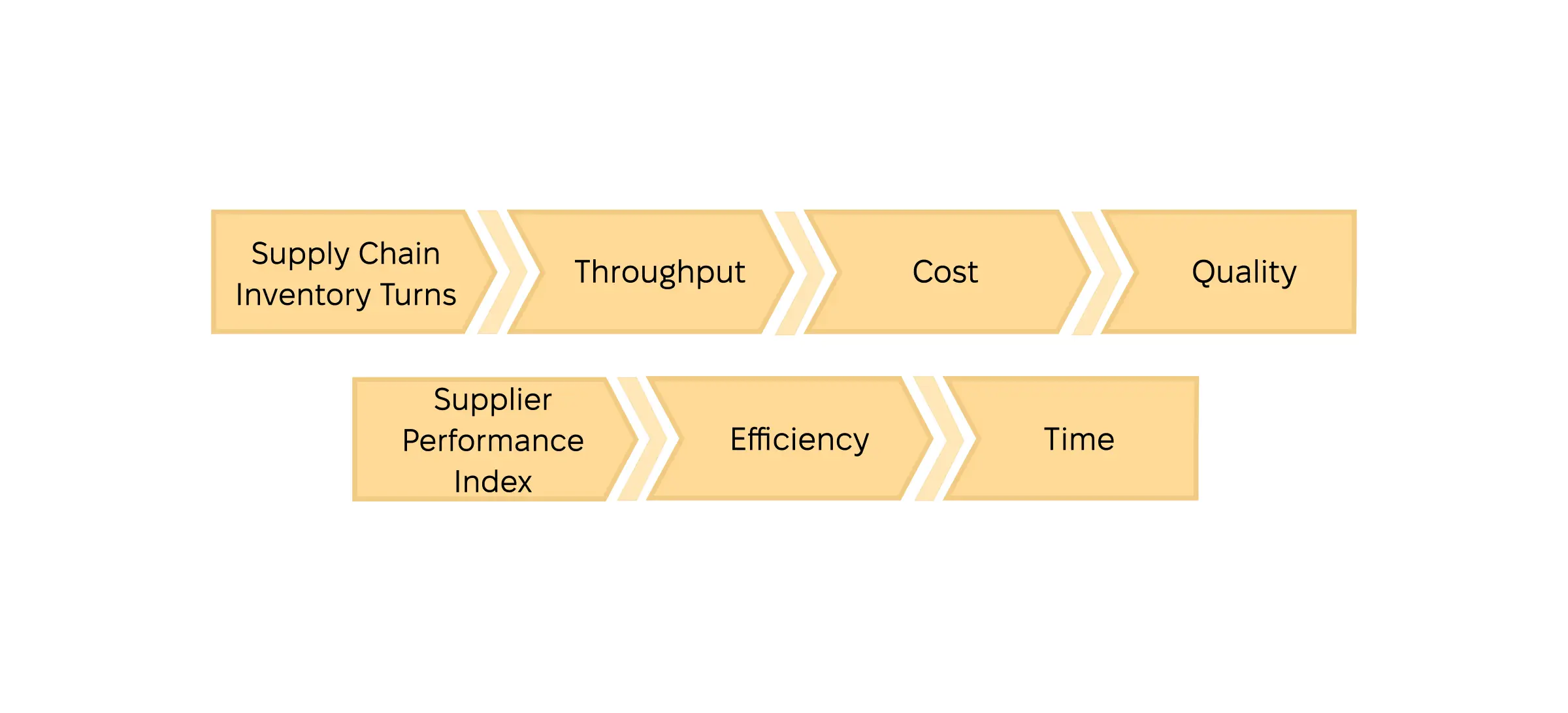

Understanding and accurately measuring efficiency metrics is paramount to incorporating supply chain improvements. This section explores key supply chain efficiency metrics for optimizing operations and fostering continuous refinement.

This metric measures how efficiently a company manages its inventory. It determines how

often inventory is sold and replaced over a specific period, typically a year.

A high turnover ratio indicates that inventory is moving quickly, which reduces storage costs

and minimizes the risk of obsolete inventory. Conversely, a low turnover ratio may signify

overstocking or slow-moving inventory, highlighting potential inefficiencies in inventory management

processes. And eventually, you must address them.

The SPI metric evaluates supplier performance across critical parameters, including lead

time, quality, cost, delivery, reliability, service level agreements (SLAs), and customer

satisfaction scores. By aggregating these factors into a single score, the SPI enables

organizations to assess supplier performance comprehensively and identify areas for

improvement.

Measuring SPI facilitates informed decision-making regarding supplier relationships and supply

chain optimization efforts, making it a vital component of effective supply chain techniques.

Throughput measures the rate at which goods move through a system or process within a specific timeframe, such as hours, days, or weeks. It provides insights into the system's capacity to process and deliver goods efficiently, helping organizations identify bottlenecks and optimize resource allocation. By maximizing throughput, companies can improve operational efficiency, reduce lead times, and enhance supply chain performance.

Efficiency metrics assess how effectively resources are used in supply chain operations. This includes evaluating the ratio of input to output, identifying and eliminating waste, and optimizing processes to minimize resource consumption and maximize productivity. Organizations can streamline operations, reduce costs, and improve supply chain performance by focusing on efficiency improvement metrics.

Time-related metrics measure the speed and timeliness of order processing, delivery lead times, and cycle times. By tracking these metrics, companies can identify areas where delays occur and implement strategies to improve process efficiency and responsiveness. By reducing lead times and cycle times, companies can enhance customer satisfaction, increase flexibility, and gain a competitive edge in the market.

Cost metrics evaluate the expenses associated with procurement, production, transportation, and inventory management. Organizations can identify cost-reduction opportunities by analyzing cost metrics, negotiating with suppliers, and optimizing spending across the supply chain. Effective cost management helps improve profitability, resource allocation, and financial sustainability.

Quality metrics assess the quality and consistency of products, services, and processes

within the supply chain. It includes monitoring defect rates, customer complaints, product

returns, and adherence to quality standards and specifications. Organizations can enhance

customer satisfaction and reduce rework and waste by maintaining high-quality standards

throughout the supply chain.

Ultimately, you foster a strong reputation for reliability and excellence, contributing to

long-term success and competitiveness.

How to improve supply chain operations? Organizations can rely on best practices to enhance efficiency and streamline operations in pursuing supply chain excellence. This section explores ten strategies to improve supply chain, showcasing innovative approaches and technologies to optimize workflows and drive sustainable growth.

Optimizing supply chain processes involves conducting a comprehensive review of the entire

workflow to identify inefficiencies and eliminate unnecessary steps. This includes

refining inventory management practices, order processing procedures, and transportation

routes.

Advanced analytics platforms and workflow automation tools facilitate supply chain process

improvement by providing real-time insights into process bottlenecks. With these software solutions,

organizations can develop optimization strategies to streamline operations, reduce cycle times,

and enhance supply chain efficiency.

Read more about

supply chain management software requirements

in our blog.

Automation improves supply chain efficiency by eliminating manual tasks, reducing errors,

and increasing operational speed. Companies can automate order processing, inventory

management, and transportation scheduling using robotic process automation (RPA) and

warehouse management system development

(WMS).

Organizations can optimize resource utilization, minimize costs, and boost productivity by

automating routine tasks and workflows.

Visibility provides insights into inventory levels, demand patterns, and logistical

operations across the supply chain network. Cloud-based inventory management systems and

real-time tracking platforms enable industry players to monitor inventory movements, track

shipments, and identify potential disruptions in real time.

These solutions facilitate better decision-making and collaboration. They provide stakeholders

access to accurate and up-to-date information, enhancing supply chain performance and customer

satisfaction.

Digital freight forwarding platforms

offer a convenient and efficient way to manage logistics operations. These online platforms

leverage artificial intelligence (AI) and machine learning (ML) to optimize freight routing,

match shipments with the most suitable carriers, and track deliveries in real time.

Digital freight forwarding platforms improve operational efficiency and reduce transportation

costs. They enhance supply chain visibility by automating manual processes and streamlining

communication between shippers, carriers, and customers. Additionally, these solutions often

integrate seamlessly with existing systems, allowing for greater interoperability and data

sharing across the supply chain ecosystem.

Demand forecasting and planning are prerequisites for optimizing inventory levels,

minimizing stockouts, and reducing carrying costs. Demand planning tools and predictive

analytics platforms use historical data, market trends, and machine learning algorithms to

forecast future demand accurately.

Predictive analytics allows companies to develop more robust demand forecasts, align inventory

levels with anticipated demand, and optimize production and procurement processes. It helps

to reduce inventory holding costs, improve inventory turnover rates, and enhance supply chain

agility.

Effective supplier relationship management ensures a reliable and resilient supply chain

network. Supplier management platforms and vendor portals enable organizations to

streamline communication, track supplier performance, and manage contracts more

efficiently.

These solutions help organizations centralize supplier-related information and automate supplier

onboarding and performance evaluations. They facilitate building stronger relationships with

suppliers, mitigating risks, and driving continuous improvement across the supply chain.

Effective inventory management helps balanceen supply and demandminimize stockouts, and

optimizeng working capital. Inventory optimization tools and RFID (Radio Frequency

Identification) systems enable organizations to track inventory levels in real time,

analyze demand patterns, and optimize replenishment strategies.

Implementing ways to improve supply chain management, such as advanced inventory tracking and

automation, improves inventory accuracy, reduces excess inventory holding costs, and enhances

supply chain resilience. Advanced inventory management systems can integrate

with demand planning and warehouse management to provide end-to-end visibility and control

over inventory-related processes.

Integrating sustainable activities into supply chain operations helps to reduce

environmental impact, meet regulatory requirements, and enhance brand reputation.

Sustainability management platforms and carbon footprint calculators enable organizations

to track and analyze environmental performance metrics across their supply chain network.

With these platforms, organizations can identify opportunities for improvement, implement sustainable

practices, and measure progress toward sustainability goals. Supply chain software solutions

can provide insights into supplier sustainability practices, enabling organizations to make

informed decisions about supplier selection and collaboration.

Continuous improvement is essential for maintaining competitiveness. Software like

performance analytics dashboards enable organizations to monitor key performance

indicators (KPIs), identify areas for improvement, and track progress toward strategic

goals.

These solutions support supply chain improvement initiatives, helping companies foster

a culture of continuous improvement, drive operational excellence, and stay ahead of

market trends and customer expectations.

Building a skilled and capable workforce to drive operational excellence is vital for

continuous supply chain improvements. Learning management systems (LMS) enable

organizations to provide employees with access to professional development opportunities

and training programs.

LMS solutions help to systematize training programs, enhancing employee skills, knowledge,

and productivity. Collaboration features facilitate knowledge sharing and teamwork among supply

chain professionals. It fosters innovation and continuous learning culture, improving supply

chain performance and business outcomes.

If you wonder how to improve your supply chain strategy, we’ve got you. Equipped with industry expertise, Exoft addresses the unique challenges logistics businesses face. Our comprehensive software solutions offer companies effective supply chain management strategies to streamline operations, automate tasks, cut operational costs, and reduce shipping time.

Partnering with Exoft ensures lower costs, improved efficiency, scalability, market competitiveness, enhanced customer satisfaction, and better risk management. Our custom software solutions help businesses improve management of the supply chain and thrive.

Modern supply chain management requires proactive strategies and innovative solutions.

Businesses can enhance their efficiency and resilience by effectively addressing

disruption and rising costs. The supply chain improvement examples, such as workflow

optimization, automation, and visibility, will help achieve sustainable growth and

maintain competitiveness.

Exoft empowers supply chain mastery through innovative custom solutions. Our innovative software

empowers businesses to streamline operations and cut costs effectively. Partnering with us

ensures efficiency, scalability, and enhanced competitiveness.

Contact us

to for an in-depth consultation on enhancing your supply chain strategy.

You can make your supply chain efficient and responsive through careful planning, streamlined processes, and agile adaptation to changing demands.

Enhancing supply chain management efficiency entails optimizing processes, leveraging technology, fostering stakeholder collaboration, and implementing relevant metrics. Supply chain inventory turns, on-time delivery rates, and order fulfillment cycle times are among the KPIs that drive supply chain improvement.

Efficient supply chain improvements can be sustainable by integrating eco-friendly practices, ethical sourcing, and waste reduction initiatives.

To improve quality in the supply chain, you can implement rigorous quality control measures, foster supplier partnerships, and leverage technology for real-time monitoring and tracking.

Hospitals, retailers, manufacturers, distributors, and consumers benefit from improved supply chain efficiency through better product availability, reduced costs, and enhanced service levels.